Intuitive Design with Enhanced User Experience The Yokogawa UT35A general-purpose temperature controller stands out with its user-friendly design. Featuring a 14-segment large color LCD display, the UT35A ensures clear and easy monitoring of vital parameters. Navigation keys complement the display, making configuration and operation straightforward even for first-time users. Additionally, the controller’s compact design—with its short depth—saves valuable space on the instrument panel, providing a practical solution for tight setups. Advanced Features for Precision and Customization The UT35A temperature controller is packed with advanced features, making it a versatile tool for various applications. Key capabilities include: Multiple Target Setpoints: The UT35A offers four target setpoints (PID numbers) as standard, allowing precise control over different process parameters. Flexible Alarm System: With three independent alarm common terminals, users can efficiently manage multiple alarm conditions. Customizable Ladder Sequences: The built-in ladder sequence function provides flexibility for tailored programming, making it ideal for complex process requirements. Extended Outputs: The controller supports up to 8 digital outputs (DOs), offering a variety of combinations to suit diverse needs. These features make the UT35A not only reliable but also adaptable to meet specific operational demands. Multi-Language Support for Global Usability Understanding the needs of a global user base, the Yokogawa UT35A comes with an operation manual available in multiple languages, including Japanese, English, German, French, Spanish, Chinese, and Korean. This ensures that operators across the world can easily understand and utilize the device. Customers can specify their desired language when placing an order, ensuring a seamless setup and operation experience. Open Network Compatibility for Modern Systems In today’s connected world, communication and data sharing are crucial. The UT35A temperature controller supports open network protocols, including Ethernet communication. This feature enhances integration with existing systems, allowing real-time data monitoring and control across various platforms. Whether used in manufacturing, research, or industrial applications, the UT35A’s connectivity capabilities improve operational efficiency. Customizable Models for Tailored Applications To cater to specific industry requirements, the Yokogawa UT35A offers a detailed code model system that allows users to customize specifications. This feature ensures that the controller can be optimized for unique applications, making it a valuable tool in diverse environments. Conclusion The Yokogawa UT35A temperature controller is a comprehensive solution for precise temperature management and process control. Its intuitive design, advanced features, global usability, and open network compatibility make it an excellent choice for industries seeking reliability and versatility. Whe...

Read More

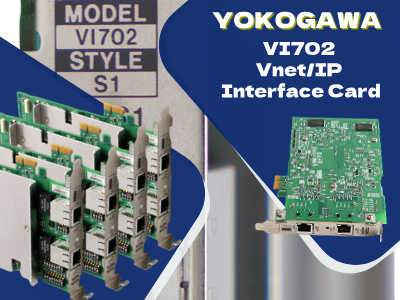

IPv6 network supported

IPv6 network supported